|

|

|

Digital Powder Dispenser Tests

Field-Testing by Froggy

GO TO SUMMARY OF TEST RESULTS

RCBS ChargeMaster Combo RCBS ChargeMaster Combo

Froggy's Bottom Line: This is the best of the three units. Dispensing speed was the best, it was easy to drain powder, controls were very user-friendly, and the zero held stable. The RCBS ChargeMaster tested had none of the vices I noticed with the other dispensers.

Good First Impressions

The first thing I noticed about the RCBS Chargemaster was how well-packaged it was for shipment. It arrived double-boxed. The unit itself was secured in high density foam inside of a thick cardboard box that was then placed into another heavy cardboard box.

Layout and Ergonomics

Like the PACT system, the RCBS ChargeMaster employs a separate scale and dispenser, but they are nicely integrated. The scale, supported on metal forks, plugs into the base of the dispenser unit so you only need one powder cord on your bench. The scale can be removed for stand-alone use, a nice feature if you're just weighing bullets or primers. The powder tray is right up front and everything is clearly visible, even with the protective clear plastic cover in position. Controls are easy to read. The powder drain is on the side, a more convenient location than the rear port on the Lyman 1200. The unit's footprint is fairly compact, so the ChargeMaster won't hog too much space on your bench-top. The only two external changes I'd like to see made in the Chargemaster would be a graduated hopper (to give you a better sense of remaining powder quantity) and a stand to get the unit up high enough to drain the powder directly into a one-pound powder bottle.

Calibrating the RCBS ChargeMaster

After the unit was unboxed and sitting on my bench, I plugged the unit in, switched it on, and the ChargeMaster immediately started to prep itself by counting down to zeros. So far, so good. Next step is to calibrate it. Here's the procedure.

The ChargeMaster comes with two 50gr calibration check-weights, which are conveniently stored in tailored recesses on the front of the unit. The calibration process takes about three minutes to complete. NOTE: The dispensing pan must be removed for the calibration process.

1. Press Calibrate on the front of the unit, then place a 50gr weight on the scale.

2. The unit will then show "50g" on the liquid crystal display.

3. Press Calibrate again, and the machine asks for the next 50gr weight. Place that on the platter and the unit will confirm the new weight.

4. Press Calibrate again, and the machine counts down to zero. Then place the powder pan on the scale, press zero and you're ready to roll.

Enter the Digital Era of Push-Button Reloading

Once you've calibrated the machine (and the display shows that the zero is stable), you can start dispensing loads or program up to 30 of your favorite reloads into memory. I really like the memory feature--after you program the unit with your favorite loads, you just press the recall button to bring up the load recipe. The only glitch is that the memory stores loads by 4-digit number. So if you have both IMR 4350 and Hodgdon 4350, for example, you have to remember which is which.

I normally fill the hopper approximately one-half full. This is more than enough for 100 cartriges of either .308 Win or 6.5-284. Now assuming that you programmed the unit for your load, place the powder pan on the scale, and press "Zero" (this resets the zero to compensate for the weight of the pan). Then hit the dispense button and the ChargeMaster starts throwing the exact charge that you programmed. In about 10-15 seconds the load's ready.

The RCBS handled long extruded powders with ease. This is important, because many manual powder measures struggle with the stick powders. The kernals jam or you have to apply extra pressure to cut them. When you do that your charge can end up quite a bit off--up to 0.5 grains. With the Charge-Master, you'll never have to re-throw a charge because of jammed kernels. However we did observe that once or twice, at the very end of the dispensing process, a few kernels would clump together, sending the charge 0.1 high. It was a simple matter to remove a couple kernels. Or, you could just dump the charge and hit "dispense" again. This is still much faster than trickling by hand.

Load Accuracy--ChargeMaster vs. Balance-Beam Scale

I checked the machine-thrown charges by weighing them with my 10-10 balance beam scale. Every automatically-dispensed charge was within ± 0.1 grain of my intended load, as measured by the balance-beam scale. But keep in mind that the balance-beam isn't foolproof either. Trying to work down to .05 grain or better accuracy requires very minute control adjustments and a lot of patience as you wait for the arm to dampen out. Remember that 0.1 grain is just three kernels of powder. Getting this to 0.1 grain accuracy level is time-consuming and frankly, I'm not convinced that the 10-10 really is demonstrably more accurate than the ChargeMaster.

In Part One of this report, another tester, Matt in Virginia, cross-checked his ChargeMaster powder throws on a 10-10 scale, and came to similar conclusions. Given the human factor, neither of us could definitively conclude which was more accurate--the ChargeMaster or the beam scale. In the future, if we can get our hands on an ultra-precise .0001gr Scientific scale, we'll revisit the issue. But I can tell you, from a real world perspective, when I went out and shot my .308 and 6.5-284, I could find no accuracy difference whatsoever between the ammo I loaded with powder dispensed by the ChargeMaster and the ammo I loaded with charges weighed on the balance-beam scale.

[EDITOR's NOTE: In the months since we tested the RCBS ChargeMaster, there have been more than a few reports of machines that had unstable zeros, or threw a charge that was, in fact, higher than the load weight reported, by as much as 0.4 grains. Accordingly, we recommend you check your ChargeMaster against a beam scale or lab scale of known accuracy. If you see a problem, particularly with overcharges, we recommend you return the unit to RCBS for replacement.]

Cleaning and Powder Removal

Cleaning the ChargeMaster is very easy (unlike the Lyman 1200). I use the lid from the powder hopper to catch the left-over powder. I place that under the drain spout, rotate the drain spout cover, and tilt the unit to the right. When you've finished, put the pan back in place and hit "trickle" to remove the last few grains in the dispensing tube.

Note that inside of the ChargeMaster's powder hold (center photo) is smooth, with curved surfaces and a natural funnel shape. So, almost all the kernels of powder drain out immediately. If you look at the pictures of the powder hold on the Lyman 1200, you can see that the RCBS has a much better design, with fewer blockage points for the kernels.

One RCBS ChargeMaster owner wrote: "I can't speak for the Lyman, but on the ChargeMaster, changing powder is as simple as can be. My scale sits on the edge of the table so I can put the powder can under the spout and open it. Once the hopper is empty, I input a charge-weight that's way above what the dispensing tube holds and let it spin itself empty into the pan. Brush out the few remaining powder kernels in the hopper base and it's done. Takes less time to do than it took me to type this."

RCBS ChargeMaster Powder Dispensing Speed Tests

We threw 20 charges with both Hodgdon H4831sc and IMR 4064, and timed the charges to completion with a stopwatch. The ChargeMaster's average "fill" times were 8.95 seconds for H4831sc and 12.3 seconds for IMR 4064. These numbers show the RCBS is roughly twice as fast as the Lyman 1200 and about 60-90% faster than the PACT. The chart below records these results. The vertical axis displays time in seconds, while the horizontal axis shows the number of the test charge, 1 through 20.

Lyman 1200 DPS II Lyman 1200 DPS II

Froggy's Bottom Line: Like the other two units, the Lyman will throw charges within ± 0.1gr. Unlike the PACT, you don't have to re-calibrate each time you change powder. That's the good news. The bad news is that warm-up is very slow, and the machine is a pain in the behind to clean. It probably took me 4-5 times as long to remove powder from the Lyman as from the PACT. The all-in-one design looks good, but it is not as versatile as the modular design of the RCBS ChargeMaster or the PACT. Lyman's warranty is only one year (vs. two years for the RCBS), and there have been some troublesome user reports of software glitches and unstable zeros, though we didn't observe these issues in our tests. While there are many happy Lyman 1200 owners, we wouldn't buy one, mainly because of the cumbersome clean-up procedure.

Layout and Ergonomics

The Lyman looks good on the bench, and doesn't take up much space front to back. Controls are convenient and the display screen is easy to read. The Lyman's one-pound powder capacity is enough for about 230 rounds of 6BR, or 150 rounds of .308 Win. The powder pan cover swings up completely out of the way. One thing we didn't like is that stray kernels tend to catch around the edges of the powder hopper cover. We would also like to see the powder drain port enlarged, and moved to the side--but that might require relocating the scale.

Scale Functions

The scale can function independently of the dispenser unit if you just want to weigh bullets, cases or primers. You can weigh items up to 1200 grains. Once warmed up, the scale seemed steady and we noticed no disturbance from air currents, and no interference from lighting or AC electrical circuits. The Lyman 1200 does have a number of built-in alarms. This may prove annoying to some users over time, but we think it's a good idea to have the machine beep when a charge is ready. Some of the other beep functions we could live without.

Good Memory Functions with PC Interface

We were impressed by the load-memory capabilities of the Lyman. It stores up to 100 loads that can be recalled by cartridge, specific powder and weight. That should cover the most active reloader's needs. No powder (flow rate) calibration is required--just select the memorized load you want, fill the hopper, and start dispensing. One cool feature that we didn't have a chance to test is the Lyman's capability to link with a personal computer. Optional PC Interface Software (sold separately) allows you to transfer loads directly from a PC to the Lyman 1200. The software also has a reloader's log for storing load data.

Long Warm-Up Time

The Lyman takes nearly a half an hour to get warmed up. For this reason, if you plan multiple reloading sessions over a day, it's best to leave it operating. NOTE: The Warm-up time for the PACT and the RCBS dispensers is a matter of a minute or so.

Cleaning and Powder Removal--A Cumbersome Task

Dumping out powder and cleaning out all remaining kernels is a tedious and time-consuming task with the Lyman 1200, compared to the other two machines. First, the powder drain port is in the rear. This requires that you pick up the machine and spin it around to access the port. We then found that quite a bit of powder typically remains. You may be tempted to tilt the machine to dump out remaining powder--but DON'T do this. You must keep the machine level and Lyman provides a brush to sweep the left-over powder out of the powder chamber. But the design of the chamber tends to trap kernels in nooks and crannies. Even after sweeping out the powder, you then need a tool to unlock the dispenser trickler tube. You use the J-hook tool to release the dispensing tube from the motor bushing. Once the tube is unlocked you can spin it to dump its contents, or slide it out completely (after capping the end), and then pull the entire powder chamber base out the back of the unit. We noted that when you snap the chamber out it's easy to fling stray kernals of powder. We also found powder can collect around the lip at the base of the powder hopper after the initial powder draining. All in all, the machine's design makes cleaning difficult and much more frustrating than it needs to be. The "invert and dump" routine of the PACT is so much easier.

|  |  | | Move unit to the edge of bench or elevate unit, then lift slider to release powder from rear port. | Drain the powder into a suitable container using the rear port. | Powder remaining after draining. Now you have to brush out the remainder. |  |  |  | | Brush out remaining powder kernels. | Remove the hopper cover, and unlock the dispensing tube. | With J-hook tool, release dispensing tube, remove last powder, then refasten the tube. |

Internal Design Traps Powder Internal Design Traps Powder

Here is a close-up of the Lyman's powder chamber. Note the numerous pockets and right-angle corners. These tend to snag powder granules, so the powder doesn't all flow out when you try to drain it. The problem is actually worse with flake powders. And users have reported problems using very fine-grain powders: "The only problem has been using fine power like AA#9 which causes the DPS to stop. Clean the powder out from the bushing/feed tube and you are good to go--but not with fine powder!" (Midway User Review). To aid in cleaning, the entire powder chamber shown in the picture can be detached from the machine. However, we found this only makes the cleaning process longer and when you snap the part out of the chassis you risk flinging powder around the unit's interior.

Some Worrisome Reports--Software and Unstable Zero

Reports from Lyman 1200 users around the country have been mostly positive.However, there are more than a few reports of software and zeroing problems, particularly with the latest DPS II version of the Lyman. (See MidwayUSA User Reviews below.) Some folks have complained of software glitches that "lock" the unit up and require restarting the machine. Others have found that the zero drifts over time--up to 1.0 grain. This requires frequent zero-checking to stay "in tune." The Lyman 1200 has a zero drift alarm that activates if zero shifts more than 0.3 grains. Lyman's instructions advise users to check zero regularly, if the Lyman's zero drift alarm is activating frequently. Yes that's a work-around, but we wonder why the zero would be shifting in the first place.

NOTE: At no point during our testing of the Lyman 1200 did we encounter software lock-up or migrating zeros, so "user error" may be the cause of some of the negative third-party reports. Still those reports give us some concern, particularly since Lyman offers only a one-year warranty with the machine. WARNING: If it's really happening, zero "drift" up to one grain could result in unsafe charges. For that matter, a charge that is more than 0.2 grains or so over a recommended max load could be unsafe.

MidwayUSA User Reviews

Lyman 1200 Powder Dispensing Speed Tests

We threw 20 charges with both Hodgdon H4831sc and IMR 4064, and timed the charge to completion with a stopwatch. The Lyman's average "fill" times were 18.9 seconds for H4831sc and 22.1 seconds for IMR 4064. This means the Lyman is signficantly slower than the RCBS for both powders. The chart below records these results. The vertical axis displays time in seconds, while the horizontal axis shows the number of the test charge, 1 through 20.

PACT Digital Dispenser and Scale PACT Digital Dispenser and Scale

Froggy's Bottom Line: The PACT is a good basic system with a clean overall design. The stand-alone scale works well by itself when you don't need dispenser capability. Our editor reports his PACT scale has been very reliable in four years of use. The dispenser unit doesn't have the ability to memorize multiple load recipes, and it can't throw charges as fast as the RCBS Chargemaster. However, clean-up was a breeze with this machine.

Layout and Ergonomics

The PACT digital powder measure is a two-part system, scale and dispenser. The two components communicate via an infra-red sensor. On the bench, you arrange scale and dispenser so that the dispenser drop tube extends right over the scale pan as shown. The PACT unit is fairly compact, with a slightly smaller envelope than the RCBS or the Lyman 1200. Footprint on the bench is small, though the powder tube extends pretty high. Exterior surfaces are smooth, without a lot of recesses or entry points for dirt, dust, or stray powder. The PACT comes with two separate 110 power supplies, one for the scale and one for the Dispenser. Both units were plugged into a surge suppressor for this test. The packaging of the unit was nicely done, with the scale unit cradled in thick, tight-fitting foam padding.

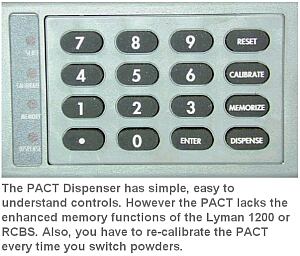

Simple Controls, but Minimal Memory Simple Controls, but Minimal Memory

Unlike the RCBS ChargeMaster and the Lyman 1200, the PACT can't be programmed to store your favorite loads. The unit's memory is limited to the current powder and load you are working on. In practice, this isn't really a big drawback, since every reloader should keep hard copy of their load data anyway. It was a simple matter of punching in the desired load weight before each load session. But of course, a recall feature would be nice, so you could avoid the input time. In reality, calibration can be a bigger time-loss. With the PACT, every time you change powder types you need to re-calibrate.

If you load multiple calibers, re-calibration becomes a big deal.

Calibrating the PACT Dispenser

Before you can load with the PACT you must first calibrate the scale unit and then calibrate the dispenser for your chosen powder. Calibrating the scale is straight-forward, but it involves using multiple weights in a sequenced order, so we'd advise you to follow the instructions that come with the machine.

Once the scale is calibrated, you then need to calibrate the powder dispenser for the particular propellant you are going to dispense. NOTE: Unlike the RCBS and Lyman 1200, this step has to be done EVERY time you change powders.

Assuming the scale has already been calibrated with check-weights, then calibrating the dispenser takes about four minutes. The process is simple:

1. Fill an appropriate amount of powder into the PACT dispenser's hopper.

2. Press the Calibration button on the dispenser

3. Wait roughly four minutes for the dispenser to calibrate to the powder you plan to dispense.

4. The pan will start to fill. When the dispenser is calibrated, a red light will let you know when the dispenser is ready.

5. Dump the powder back into the hopper and you're ready to go.

Cleaning and Removing Powder--Where the PACT Really Shines

The PACT is the easiest of the three dispensers to clean. You simply unplug the dispenser, and place a funnel or a measuring cup under the hopper. Then turn the unit upside down and dump out the powder. When it's empty, plug the unit back in, and trickle the rest out of the dispensing tubes. NOTE: the PACT has two dispensing tubes, one for high speed the other for low speed trickling. Make sure both tubes are empty. It really is a very simple and fast process to dump out powder. Removing powder from the PACT can be done in a fraction of the time the clean-up process takes with the Lyman 1200.

A Suggestion for Improvement

For those that are buzzer or beeper sensitive you'll love the fact that there are no beeps or audible alarms on the PACT. However, I think this is not a good thing for most of us. I had to constantly monitor the machine to see when my load was dispensed. That's wasted time that could have been used seating bullets. A simple chime (on charge completion) would be very helpful.

PACT Powder Dispensing Speed Tests

We threw 20 charges with both Hodgdon H4831sc and IMR 4064, and timed the charge to completion with a stopwatch. The PACT's average "fill" times were 14.65 seconds for H4831 and 22.5 seconds for IMR 4064. This means the PACT is signficantly slower than the RCBS for both powders. The chart below records these results. The vertical axis displays time in seconds, while the horizontal axis shows the number of the test charge, 1 through 20. (NOTE: The PACT dispenser we tested has the current, "high-speed" PACT internals. The older PACT dispensers are about three times slower.)

Note from Froggy: I shoot two rifle calibers, the ever popular .308 Win and my 6.5-284. The tested charge weights listed in the article are pretty much standard but do NOT use them as load recipes. Consult a current load manual from the powder-maker, start 10% low, and work up.

This article contains my own opinions and those of 6mmBR.com. The timing data used in this article was acquired from a crude but accurate stop watch. My intention is to show the consumer what is available and which unit, in my opinion, best meets my needs as far as speed and accuracy go. I do not in any way mean to dispute the specifications or parameters set forth by the manufacturers' directions for use. Writing this article is an attempt to show consumers what is available and what to expect from these types of dispensers.

For many years I have been a firm believer that a balance-beam scale is the only way to go for accurate reloads. Well, ignorance is bliss. This proves that teaching old dogs new tricks CAN be done. I personally own an RCBS 10-10 scale and, over the years, I've spent countless hours manually weighing each load. From now on, that's going to change.

I've discovered that the digital dispensing system can indeed speed up my reloading process considerably. That means less time at my reloading bench and more time at the range. And, my recent targets have convinced me that the ammo I've produced with digital dispensers is no less accurate than the ammo I filled with powder thrown and weighed by hand. |

Edited by Paul McM. All content Copyright © 2005, 6mmBR.com, All Rights Reserved.

No reproduction of any content without advanced permission in writing.

Topics: Scale, Digital, Dispenser, Powder Measure, Accuracy, Reloading, Testing, RCBS, RCBS 1500, ChargeMaster, ChargeMaster Combo, Ohaus, 10-10, 505, Lyman, Lyman 1200, DPS, PACT, PACT scale, Calibration, Calibrate, 6mm, 6mm BR, 6BR, 6.5, 6.5mm, 6.5-284, 6PPC, Target Rifle, Benchrest, BR, Bench Rest, Single-shot, competition, rifle accuracy, BC, Ballistics, Norma, Hodgdon Powder, H4831, H4831sc, IMR, IMR 4064, Sierra, MatchKing, Competition Shooting, barrel, reloading, powder, bullets, precision, shooting, hunting, Lean Manufacturing.

|

|