Profile:

Profile: Dave Kiff directs the operation of

Pacific Tool & Gauge, the premier custom reamer maker on the West Coast. His reamers have been used on many match-winning rifles, both in standard 6BR and 6 BR Improved chamberings. The man knows his stuff. When you give him a call, he will listen carefully to your design goals, and provide you with a custom reamer ideally suited to your needs, delivered quickly, at a fair price.

6mmBR.com asked Dave about PT&G and what is involved in designing and machining a custom reamer for a 6BR rifle.

Q: Dave, tell us about Pacific Tool & Gauge...

We manufacture precision chamber reamers, gauges and a wide variety of other specialty tools for the firearms industry including Remington replacement bolts for benchrest rifles. We've grown from a two-person operation to a 34-employee shop, doing work for all the major gun manufacturers. At the same time we take pride in our custom work, providing one-on-one service for each individual customer. I've been doing precision machining for over 20 years, and I learned about making reamers from some of the best tool-makers in the business, Keith Francis and Red Elliot.

Q: What sets PT&G apart from other firms that produce reamers?

We are one of the only companies that still handcrafts reamers on Crystal-Lake belt driven grinders. I also personally hand-stone each and every PT&G reamer that leaves our doors. Unlike other companies, we do not charge extra for wildcats like the 6 Dasher, nor do we charge extra to custom-spec your reamer from your dummy case. And our track record in competition in unsurpassed. In fact, a new world record was recently set with a 6 Dasher chambered with a PT&G reamer.

Q: What are the advantages of a custom PT&G reamer--What do I get for my $138 investment?

You get better accuracy, reduced ES, longer brass life, and most importantly you get exactly the chamber that you want. The throat will be set precisely to match the bullets you shoot and the seating depth you want. And you can pick a neck-size to suit your needs. Whether you want a .272" no-turn neck or a minimum-turn .269" neck (which is very popular now), we can make that, or any other neck diameter you want all the way down to .261". Because you can set the exact neck-wall thickness you want, you get better control over neck tension which reduces velocity spreads. And the body dimensions are ideally matched to Lapua brass so you get less case expansion, without sacrificing feed reliabilty. Brass that isn't worked as much during sizing lasts longer.

Let me give you an example of how important a good chamber is. We've seen super-expensive barrels on thousand-dollar actions that did not shoot well at all, because the throating was bad. The throat will make or break a benchrest gun. When they were rechambered with our reamers, group size was reduced by 50% or more. We've had other customers that start out with non-premium, inexpensive barrels, but still end up with very competitive guns because they have perfect chambers and throats. A concentric, close-fitting chamber and a good throat are the keys to accuracy.

Q: Without revealing any trade secrets, what throat lengths do you recommend for a 6mm BR case?

We normally go with a 1.5 degree lead angle, unless the customer wants something different. For 60-68gr bullets we recommend a .060" freebore. For the 80gr bullets, .080" is a good setting. For the 100-107gr VLDs, a .115" -.120" freebore will allow you to get the base of the bullet up out of the doughnut area. This will save you lots of aggravation over the life of the barrel.

Q: There are a variety of 6BR Improved case profiles out there. Which wildcat version works best, based on reports from your customers?

We have prints for all the popular 6 Improved cases including the Dasher, the 6 BRBS (Shehane), and Bob Crone's 6 BRX. Based on customer reports, it is our strong opinion that the 6 Dasher is by far the best for 1000-yard accuracy. You get a bit longer neck, and the Dasher has a 40° Improved body. This 40° shoulder provides the most ideal turbulence pattern for consistent powder ignition. Bottom line, the 6 Dasher is the winningest 1000yd cartridge based on the 6mm BR parent case. If I built a 6BR wildcat rifle for myself, it would definitely be a Dasher.

Q: What kind of chambering reamers are preferred by your customers?

By far, the majority of our custom reamer orders are for removable-pilot reamers (live pilot) for the full chamber (neck and body). Definitely go with a live pilot for any custom reamer you have ground. Solid piloted reamers can scratch the lands.

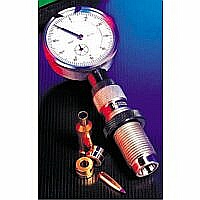

Live-Pilot Reamer from ECT (Elliot Tool), a PT&G company.

Q: What about neck-only reamers--do you recommend doing the neck with a separate neck reamer?

No. We always recommend using a full neck+body reamer for a high-grade custom rifle, particularly if you plan to have more than one barrel. Yes, a very talented smith can finish a chamber with a separate neck reamer (which we sell), but to get absolute 100% consistency from barrel to barrel it is best to cut the chamber with our live pilot reamer that does the neck and body at the same time. When the barrel is shot out, you can take that reamer, give it to any good smith, and get an identical chamber.

Q: If my smith has a 6BR reamer in stock, why should I buy my own reamer from PT&G?

First and foremost, we can give you a reamer with the throat set ideally from your dummy round, with freebore measured from the bullet ogive. And the body diameter will be a perfect fit for Lapua brass. Having the throat and lead set for your case and bullet choice will provide the best accuracy for the gun. You can spend thousands on your action, barrel, stock and scope, but if the throat is not right, your gun may not shoot to your expectations.

Also, consider that your smith's reamer may be an older model designed for 6 BR Remington brass. This will cut a chamber dimensionally incorrect for Lapua brass. The neck will be short and it will be tight at the casehead. Second, if it is a full SAMMI-spec reamer you may end up with a neck diameter much larger than you want, .276" or even larger, when .272" is all you need for a no-turn neck. Order from us and we can give you precisely the dimensions you want for both neck and body. Lastly, your smith's reamer may have a lot of miles on it. Worn-out reamers cut poor chambers.

We always recommend that you use a sharp reamer that cuts on all flutes. A worn reamer or a reamer that does not cut on all flutes can give you a small or short throat also a larger body than needed. Always check your reamer before you use it.

Q: How long does it take to get a 6mm BR or 6BR improved reamer? Does the customer need to send you a spec sheet or can you work off a sample round?

When a customer calls, I ask what brass he will be using and what bullet he plans to shoot. I can usually spec the right throat length and headspace based on this information alone, but it is best if he sends a dummy round with a bullet seated exactly where he wants it--for example with the top of the boat-tail .050" above the neck-shoulder junction. I measure the dummy round off the ogive with a 100-power Deltronic comparator, inspect for concentricity and gauge the headspace. Then I prepare a print for the job right away. The completed reamer is usually ready in two to six weeks.

Q: Do you sell non-custom 6BR reamers as well?

Yes, through MidwayUSA we sell both a $89 SAAMI standard 6mm BR Norma reamer (solid pilot) and a $105 Match Grade reamer (live pilot). These are produced by our subsidiary ECT (Elliot Tool Company), but I still personally hand-finish the Match Grade reamers. The Match Grade 6BR reamer, Midway item # 555174, features a .272" no-turn neck and a .113" freebore. This is ideal for shooting 107gr Sierra MKs with a no-turn neck, or shooting Lapua factory-loaded 105gr ammo. This is a great value for anyone wanting to shoot the 100gr bullets with a no-turn neck. And you can buy it off the shelf. And let your readers know we also stock off-the-shelf reamers for Tubb's 6XC cartridge and the 6x47 Swiss Match.

Q: Last Question. Do you have any new products in the pipeline we should be looking for?

Yes, we have a number of projects in the works, but I think your readers will be most interested in our new precision-made Remington replacement bolt. It is available with either a Rem standard extractor or a Sako-style extractor for $125. The tolerances rival that of the bolts found in custom actions.

Pacific Tool & GaugeP.O. Box 2549 - 598 Ave C

White City, OR 97503

Phone: (541) 826-5808; FAX: (541) 826-5304

Copyright © 2004, 6mmBR.com, All Rights Reserved. No reproduction without advanced permission in writing.

Copyright © 2004, 6mmBR.com, All Rights Reserved. No reproduction without advanced permission in writing.