|

Beckmann's BRX

A Winning Rifle for Grand-dad and the Youngins

Other Guns of the Week >

When Frank Beckmann set out to build a nice, light-recoiling long-distance rifle for his grandchildren, little did he know that it would prove capable of winning trophies and setting records. It took a while to get everything dialed in, but now Frank owns one of the most successful F-Class rigs on the East Coast. At his very first competition, the Southeast Shootout, he won two of five matches. A month later, at the 2005 F-Class Nationals, Frank posted a remarkable 150-23X score. Not bad for a true newcomer. Frank proves that, with a good rifle, and attention to detail, even a novice can grab some glory.

Match-Winning 6mm BRX

by Frank Beckmann

How the Project Got Started

First of all, I'll admit that I'm not an experienced competitive shooter. Hunting was my only real shooting interest over the years. I wasn't planning to get into competition. The BRX was really built for my two grandchildren, both of whom are interested in shooting, have excellent eyesight, and took top honors at a local Police Academy summer camp for children.

Before the BRX was built, starting last spring, I had used my old .222 Remington model 722 to teach marksmanship to the grand-kids. I put a Weaver T-36 on the .222 and we took them to Knoxville area ranges for shooting sessions. With their 20/15 eyesight, the kids ended up shooting better than I could. But I could tell the rifle wasn't up to their capabilities and I wanted something better for them. So, I picked the brains of a very gun-savvy shooting friend, Glenn Strickland, and started reading info from the 6mmBR.com site and Precision Shooting magazine

Oak Ridge, Tennessee--the BRX's home turf. It's one beautiful place to shoot.

As luck would have it, Glenn and I met Greg Siegmund (Clinch River Bullets). Greg ran the Monday Highpower league at nearby Oak Ridge. Greg invited us to shoot at Oak Ridge and go with him to the Piedmont benchrest match in June. At Piedmont, we met Mike Davis, a gunsmith from Zionville, NC, (828) 297-1562. From that point, the project really started coming together. One month after ordering the parts, I was shooting the new BRX.

Building the Rifle and Shooting my First Big Match Building the Rifle and Shooting my First Big Match

I wanted a center-fire rifle for the kids that would be flexible, accurate and have mild recoil. I relied heavily on Precision Shooting and 6mmBR.com for data, and everything kept pointing toward the Lapua 6mm BR case. I read a lot about the Dasher and the 6 BRX. After ordering an action from Bruno's, my original plan was to get two barrels--a 6mm 8-twist for a 6BR Improved and a .308 slow-twist for a 30 BR, but I ended up just ordering the 6mm.

I was leaning slightly toward the Dasher and would have hired Dave Tooley to smith it, but he was scheduled for a medical operation, so that would have delayed things. When I met Mike Davis at the June Piedmont meet and learned he was smithing the 6BRX, the decision was made for me--the rifle would be a 6BRX.

Several weeks later I had worked up a good load, so I took the BRX to Oak Ridge where it tested quite well at 1000 yards. With strong urging from Greg Siegmund, in September I entered my first-ever competition, and first-ever "belly match", the 1000-Yard F-Class Southeast Shootout. The gods smiled on me that day as I managed to win two of the five matches, and shot High Score (200-18X). Not bad for starters. In October, I competed in the F-Class Nationals and surpassed all my expectations. Highlight of that match was shooting a 150-23X target, which, I was told, had never been done before. That makes it a "Provisional" F-Class record, pending the setting of final standards by the NRA. If you're curious about the scoring, I drilled 15 straight shots in the X-Ring to amass a "perfect" 150 points, 15 Xs. Under the NRA's continuation rule I was then allowed to shoot for X-count (until I dropped one into the 10-Ring). I hit 8 more Xs for a total of 23X, but that didn't alter the point total. Shot 24 barely missed the X-Ring, by less than 1/2". Several weeks later I had worked up a good load, so I took the BRX to Oak Ridge where it tested quite well at 1000 yards. With strong urging from Greg Siegmund, in September I entered my first-ever competition, and first-ever "belly match", the 1000-Yard F-Class Southeast Shootout. The gods smiled on me that day as I managed to win two of the five matches, and shot High Score (200-18X). Not bad for starters. In October, I competed in the F-Class Nationals and surpassed all my expectations. Highlight of that match was shooting a 150-23X target, which, I was told, had never been done before. That makes it a "Provisional" F-Class record, pending the setting of final standards by the NRA. If you're curious about the scoring, I drilled 15 straight shots in the X-Ring to amass a "perfect" 150 points, 15 Xs. Under the NRA's continuation rule I was then allowed to shoot for X-count (until I dropped one into the 10-Ring). I hit 8 more Xs for a total of 23X, but that didn't alter the point total. Shot 24 barely missed the X-Ring, by less than 1/2".

Rifle Components and Gunsmithing

In May of 2005 I didn't know diddly about custom guns or custom actions. All I knew was what I was able to glean from the various manufacturers' web sites. But with the novice's ignorance, I called Bruno Shooters Supply and told them I wanted a Right Bolt, Left Port single shot action that would handle the 6 BRX or the Dasher. Bruno's had just one such action in stock, a Nesika K model. When I asked "what's a K model?", I was told that it was longer than a J model and could handle cases bigger than a .308. I liked the chambering flexibility that allowed, so I ordered the Nesika K and a trigger guard.

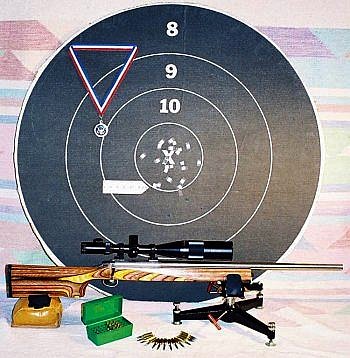

To the new Nesika action, Mike Davis fitted a 2 oz. Shilen trigger, and a 28" Shilen Select Match 1:8" twist, 8-groove, HV barrel. Mike chambered the barrel with 6 BRX reamer with no-turn .272" neck, and .120" freebore. The Desert Camo laminated long-range BR stock is from Richard's Custom Rifles. Initially, for optics, I used a Weaver T-36 with fine crosshair, set in Burris Signature rings with elevation inserts. I used the T-36 at the SE Shootout and the F-Class Nationals. At the Shootout, the morning mist and afternoon haze really bothered me while looking through the Weaver--the high fixed magnification make the mist/haze more opaque. So, I've upgraded to a Nightforce 12-42X (with special order CH-1 fine crosshair). Getting a variable-power scope and being able to reduce power helped with the haze, and lets me better see what the wind is doing to the shooters beside me. To the new Nesika action, Mike Davis fitted a 2 oz. Shilen trigger, and a 28" Shilen Select Match 1:8" twist, 8-groove, HV barrel. Mike chambered the barrel with 6 BRX reamer with no-turn .272" neck, and .120" freebore. The Desert Camo laminated long-range BR stock is from Richard's Custom Rifles. Initially, for optics, I used a Weaver T-36 with fine crosshair, set in Burris Signature rings with elevation inserts. I used the T-36 at the SE Shootout and the F-Class Nationals. At the Shootout, the morning mist and afternoon haze really bothered me while looking through the Weaver--the high fixed magnification make the mist/haze more opaque. So, I've upgraded to a Nightforce 12-42X (with special order CH-1 fine crosshair). Getting a variable-power scope and being able to reduce power helped with the haze, and lets me better see what the wind is doing to the shooters beside me.

Beckmann's "Secret Weapon" -- A $3.00 Barrel "Tuner" That Really Works

I do have one "trick" component on my BRX, a home-made barrel tuner/tensioner in the stock's fore-arm. (See "Bughole Tuner" article in the June 2005, issue of Precision Shooting.) Necessity was indeed the mother of invention here. For quite a while, I had real difficulties getting this rifle to shoot accurately. My ladder tests showed unpredictable shot scattering with just 0.1 grain changes in powder. It was very sensitive to seating depth and powder charge. I had almost given up on it until I made the "tuner" and finally saw that it could shoot reasonable groups.

The "tuner" is very simple and cost less than $3. It takes just a little planning and measuring to make. I went to a hardware store and bought a stainless ¼"-20 Phillips head bolt 1-1/2" long and a threaded ¼" thick by ½" diameter Delrin washer. I ground the bolt head diameter down to shank size and cut to 1" OAL. I drilled a centered, slightly-angled (to account for barrel taper) hole completely through the stock using a 3/8" drill bit. On the barrel channel side, I drilled out a slightly over-sized hole about 3/16" deep that was just a bit larger than the ½" Delrin washer. I ran the Delrin ring flush with the end of the bolt and Super-Glued it in place. I waxed the bolt, washer and bottom of barrel thoroughly with auto paste wax, filled the 3/8" hole in the stock with JB Weld (which I first allowed to partially set up), inserted the bolt-washer assembly into the hole. Then I bolted the action in place and turned everything upside down, making sure the Delrin washer was in contact with the barrel. When the JB Weld is dry, an easy twist with a screwdriver breaks the waxed bolt threads loose and you can run the bolt-washer assembly up and down in the threaded JB Weld you made. The "tuner" is very simple and cost less than $3. It takes just a little planning and measuring to make. I went to a hardware store and bought a stainless ¼"-20 Phillips head bolt 1-1/2" long and a threaded ¼" thick by ½" diameter Delrin washer. I ground the bolt head diameter down to shank size and cut to 1" OAL. I drilled a centered, slightly-angled (to account for barrel taper) hole completely through the stock using a 3/8" drill bit. On the barrel channel side, I drilled out a slightly over-sized hole about 3/16" deep that was just a bit larger than the ½" Delrin washer. I ran the Delrin ring flush with the end of the bolt and Super-Glued it in place. I waxed the bolt, washer and bottom of barrel thoroughly with auto paste wax, filled the 3/8" hole in the stock with JB Weld (which I first allowed to partially set up), inserted the bolt-washer assembly into the hole. Then I bolted the action in place and turned everything upside down, making sure the Delrin washer was in contact with the barrel. When the JB Weld is dry, an easy twist with a screwdriver breaks the waxed bolt threads loose and you can run the bolt-washer assembly up and down in the threaded JB Weld you made.

How does it work? Very effectively. I found, with some loads, just a minimal amount of tension or pressure would shrink groups up to 50%. Even just a whisper of pressure could affect the groups. |

Load Development--The Circular Road to Success

To make a long story short, I eventually learned my BRX likes hot loads with the Sierra 107s way into the lands. Unfortunately, I wasted a lot of time and ammo following the wrong (for my rifle) advice on powder charge and seating depth. Take heed and you may learn something from my experience and save time. Initially, I went through just about all possible combinations of powder charge and seating depths--from 33 to 35 grains of Varget and from .020" out of the lands to almost touching the lands. Every target looked like a poor shotgun pattern.

After a month of this nonsense I went back and re-read my first set of fire-forming notes. Then the lights came on. When I first fire-formed in June of 2005, all 50 original shots went into a ragged half-inch hole at 100 meters and I had come home to write "Wow, this baby shoots." Scanning over the fire-forming records, I concluded the reason it shot well was because it liked pressure. When I picked up the barreled action from Mike Davis, he told me to fire-form using a .265" neck die, 31.0 grains of Varget, really jam the bullet into the lands, and then go to a .267 neck bushing after forming. I re-read in my notes that I had followed his advice and jammed the 107 SMKs into the lands. I didn't really know how much land contact he meant with his advice to "jam into the lands" so I seated the bullets out until I got a .070" scuff on the 107 SMKs. I feel that's why my rifle shot well while fire-forming. After a month of this nonsense I went back and re-read my first set of fire-forming notes. Then the lights came on. When I first fire-formed in June of 2005, all 50 original shots went into a ragged half-inch hole at 100 meters and I had come home to write "Wow, this baby shoots." Scanning over the fire-forming records, I concluded the reason it shot well was because it liked pressure. When I picked up the barreled action from Mike Davis, he told me to fire-form using a .265" neck die, 31.0 grains of Varget, really jam the bullet into the lands, and then go to a .267 neck bushing after forming. I re-read in my notes that I had followed his advice and jammed the 107 SMKs into the lands. I didn't really know how much land contact he meant with his advice to "jam into the lands" so I seated the bullets out until I got a .070" scuff on the 107 SMKs. I feel that's why my rifle shot well while fire-forming.

So, back on track, I started moving the bullets into the lands .005" at a time. The groups started shrinking and I moved my targets out to 200 meters. When I found a setting that grouped reasonably tight, I tried tweaking it by altering powder charge and/or using the my home-made "tuner", actually just a button that applies pressure on the bottom of the barrel. That simple "tuner" (or tensioner) worked quite well. With only the slightest barrel contact the groups with some loads shrank by as much as 50% while others, maybe already at maximum, would slightly enlarge.

As I pushed the bullets further into the lands, the amount of powder started becoming critical, with noticeable changes in bullet impact every two-tenths grains or so. I found that 33.7 grains of Varget with the bullet well into the lands would shoot pretty well at 200 meters, with repeatable three-shot groups around ¼" without using the "tuner". I almost lost sight of that fact when I performed the side by side ladder test (on Greg Siegmund's suggestion) with charges of 33.0 to 34.5 grains of Varget in .1 grain increments. Bullets were seated as close to 0.0" touch as I could measure. The ladder test, shot at 200 meters in perfectly calm early morning air with no mirage, produced some weird groups, but one repeatable ¼" at 33.2 grains and an un-repeatable 5/16" at 34.0 grains. Overall group placements climbed over 1" from lowest to highest charge. Click Here to view the oversize target sheet I used for ladder testing. This made it very easy to compare many groups at a glance.

| 6 BRX Match Load | 33.7 grains Varget

.267" Neck Bushing

Federal 205M primers

Sierra 107 MKs (moly-coat)

Bullets .035" into lands

No "tuner" tension |

| I loaded up about 15 rounds at 0.0" seating depth and 33.2 grains of Varget, another 15 rounds with the bullets seated .035" into the lands with 33.7 grains of Varget and took them to the Oak Ridge 1000 yard range on a warm and mildly breezy afternoon. The 33.2 grain loads "felt soft" and only half of them went into the X-Ring, while most of the 33.7 grain loads went into the X-Ring. So, I chose the higher charge with the bullets deeply jammed. This load, running 3025 FPS with ES in the teens, is what I've used in four competitions to date, and it's worked very well in all of them. |

Top Guns--Next Generation Top Guns--Next Generation

I put the rifle together for my grandchildren and I thought you might enjoy seeing this photo of them. We live through our children and grandchildren. My granddaughter Mackenzie, 13, and my grandson Avery, are both natural shooters with exceptional eyesight and lack of bad habits. It's a hoot to observe their interest in shooting. They "eat up" everything I tell them about reloading and shooting. Both of them know how to "roll their own" ammo and won't let me reload for them.

Two days after the F-Class Nationals, I took them to Oak Ridge to shoot 1000 yards for the first time. See the photo of them with their combined target. Prior to this shooting session, the grand-kids had each shot my rifle just once, at a distance of only 100 meters. This photo shows a combined 30 shots (15 shots each) at 1000 yards two days after the BRX rifle shot the 23X score. This was their first time ever to shoot 1000 yards. If this rifle keeps shooting and the kids maintain their interest, they may put the record clear out of sight. I plan to turn both of them loose on the "big dogs" this year. |

Reloading Methods and Equipment

I do everything reasonable with my reloading equipment, procedures, and components to eliminate variances. I use a Tanita jeweler's scale which is accurate +/- .05 grains. Two granules of Varget tick the readout up another .05 grains on this scale. I adjust my powder measure to throw an underweight charge into the pan and trickle granules out of a hollow brass tube inserted into a square balsa handle until one granule ticks the readout up to 33.7.

I have a meplat trimmer but have not used it. I measure and sort bullet bearing lengths on the SMKs into .001" increments (lordy how many dies did they come out of!?), and weight-sort new Lapua 6mm brass into 0.1 grain increments. I shoot similar (within .3 grains of each other) cases together and only the sorted .001" bearing-length batches of bullets in competition. After fire-forming, I chamfer the neck openings and polish the inside of the case necks with 0000 steel wool. This polish job virtually eliminates case-manufacturing irregularities inside the necks that dig into the bullets, and the polish job lasts a long, long time.

I want all my cases to start out virtually the same every time I load them. In my rifle the wide variation in crud buildup in the necks within a group of once-fired cases can be detected by pushing a bullet into the cases by hand. Some just drop to the bottom of the case, while I have to really push on others. For me, not cleaning the necks results in poor performance at 1000 yards. So, every case I shoot in competition gets dunked in Iosso case cleaning liquid after being fired. It then is placed into a sink of hot water, swabbed out with a Q-tip and running water, and thrown into my tumbler for an hour or so to absorb any water. It emerges clean inside and out. This is the most labor-intensive thing I do (I need one of those ultrasonic cleaners).

I don't ream or try to improve flash holes in Lapua cases. I do clean the primer pocket after each shot, never turn anything off the neck, and size the neck to within 3/64ths inch of the neck-shoulder junction. I use WD-40 for a sizing lube. After the fourth shot on a new case, I body-size the cases after every shot to bump the shoulders back. After 8-10 reloadings I trim all cases to the same length (lengths of my new Lapua brass have been very consistent).

I use a standard set of Redding 6mm BR competition dies. I raised the body-sizing die .098" in the press…this gives me a finished .001" shoulder bump on my cases. I've not found, in 20 reloadings of each case, any need to size any more of the case than this modification yields. To date, in 1800 rounds, I've had only 2 split necks and 2 cases that got sticky in the shellholder. I get about 18-20 reloads per case before the primer pockets get too loose.

Cleaning Techniques

I shoot about 100 rounds between bore cleanings. I apply Gunslick Foam a couple of times (and let sit overnight each time), dry-patch with paper towel patches and stroke with a dry nylon brush and dry patch some more after each application. Two treatments with the foam gets most of the copper out. I then wet patch a few times with Hoppe's, dry-patch with the paper towel patches, and use the dry nylon brush between the paper patches. I continue with the Hoppe's until the bore is almost clean of powder and moly fouling. I have learned that a "squeaky clean" barrel requires too many fouling shots.

Beckmann's BRX--Four Times a Winner

Despite my inexperience as a competitor, and my odd shooting form (like an "alligator wallering" because of the RBLP configuration) my rifle has placed well in the four major matches I've shot since September. Despite my inexperience as a competitor, and my odd shooting form (like an "alligator wallering" because of the RBLP configuration) my rifle has placed well in the four major matches I've shot since September.

Southeast 1000-Yard Shootout, 9/23/05

I won two of five matches and took top score with a 200-18X. Before this event I knew nothing about competition, match procedures/format/terminology and I hadn't shot from my belly since age 15. After the ShootOut I decided that since my rifle had shot well enough to beat Walter Stroman twice I would halt load development for a while.

F-Class Nationals, 1000 Yards, 10/8/05

My 6 BRX shot the top score of 150-23X. The NRA rep at the meet examined the target and reported the results to NRA as a provisional record. Interesting that I wouldn't even have known about the Nationals except for some casual talk I overheard at the SE Shootout two weeks earlier. (Told you, competition was not my game!) I decided "what the heck" and called Clyde "Rusty" Nail, Match Director. He said he'd received a couple of cancellations and I took one of them. I decided not to shoot the 600-yard matches in the day-long Friday rain.

Regional 3x600 at Oak Ridge, 11/13/05

I posted top Aggregate of 600-56Xs for the meet, but no kewpie doll…only three of the shooters were F-Class. Unfortunately, I dropped four Xs for being sloppy. This was the first time for me and the rifle at 600 yards. I wisely went to the Oak Ridge range the day before the match to re-zero the rifle.

Regional WCRC 2x1000 at Tullahoma, 12/18/05

Here I scored top Aggregate (397-20X) and won a free pass to their next shoot. I had never been to the Arnold AFB range before. In my haste to get started on the three-hour drive to the range, I picked up the wrong box of cartridges--a combination of 107gr SMKs and 105gr Lapua Scenars that I'd loaded for a 200-yard comparison test at home. Sooo, they got tested at 1000 instead and seemed to be equal at the target. I did not see the Lapuas impacting higher than the SMKs like some say they would, but my shots were erratic anyway since I do not read wind well.

Going for a 1000-Yard Record--How I Nearly Made a Big Mistake Going for a 1000-Yard Record--How I Nearly Made a Big Mistake

Overall, it's been an amazing ride. My score at the F-Class Nationals was sure a surprise. The rifle was shooting so well that 23X did not seem like much of an accomplishment to me and I didn't expect "the record" (even though provisional) to last the day out. Strange how it happened. After I'd shot 15 Xs, Chris "FatBoy" Hayes, my scorer, said "Well done" and walked off to turn in my score card. Ignorant of the continuation rule, I went back to my chair and sat down. In a few minutes Chris came running back, calling himself a dummy, and told me I could go back to the line and shoot for a record. Not knowing what the record was, and I didn't think to ask Chris, I wondered at the odds of laying back down and picking up where I'd left off. I almost declined. The fact that the rifle was still shooting like a laser was amazing. Being on station #22 at the extreme far right end of the firing line, I was oblivious to everything to my left and behind me, except for hearing Rusty calling an end to all allowed-time shooting just as my shot #18 went into the X-Ring. I understand the tension along the line and in the pits started revving up a little when shot #20 went into the X-Ring. I was too amazed watching each X get posted to get nervous.

Given the right load and such mild recoil, shooting this rifle is effortless. I'm continually amazed at even hitting the target consistently, let alone the X-Ring, at 1000 yards. In more capable hands at the Nationals that day, the rifle could have put the record totally out of sight.

[Note on photo: At 7 o'clock just outside the X-Ring, shot #24 leaked out of the center to break the string. If I had been paying attention to shots getting progressively lower I might have caught that. The 6 BRX was just greasing the bullets that day.]

Looking to the Future--Plans for 2006

I am never satisfied with sitting on an accuracy plateau, and am not assuming that my rifle will be competitive on the smaller X-Rings the NRA has recently approved for F-Class matches.

The game will change. When I put a 5" circle on my record target, it only covered 14 holes! I need to refine the rifle's capabilities. Jackie Schmidt's 6BR test comes at a good time for me. I read his results with keen interest and his comment about the occasional flyers using Varget is consistent with my experiences. Based on Jackie's initial tests, I will give the RL-15 powder a try. I will probably also switch to CCI primers. I recently conducted some side-by-side tests of the Federal 205M primers vs. both versions of the CCIs (BR4 and 450) and have measured a decrease in group size of about 20% at 200 yards using the BR-4s. Since I experienced two pierced primers in competition using Federal 205M primers, I now have plenty of incentive to change to the CCIs. Taking a bolt apart during a match to remove the primer fragment is not good.

— Frank Beckmann — |

Copyright © 2006, 6mmBR.com | AccurateShooter.com, All Rights Reserved.

No reproduction of any content without advanced permission in writing.

Topics: 6mm, 6mm BR, 6BR, 6BR BS, 6.5-284, Shilen, Nesika, Richard's Custom Rifles, Laminated, 1000 yards, NRA, FClass, F-Class, F Open, IBS, NBRSA, Sierra, 107, MatchKing, Match-King, Hodgdon, Varget, Jewell trigger, Benchrest, BR, Bench Rest, Single-shot, competition, rifle accuracy, Norma, Hodgdon Powder, Varget, Vihtavuori, N150, N540, Berger, Weaver, T36, T-36, Nightforce, 105, Lapua Scenar, 1000yd stock, F-Class, stocks, McMillan, BAT Machines, Hall Action, stainless barrel, reloading, powder, case forming, Neck-turning, .262, .271, No-Turn, Lapua Brass, Clinch River Greg Siegmund, bullets, precision.

|