|

Speedy's 6PPC -- The Art of Accuracy

Other Guns of the Week >

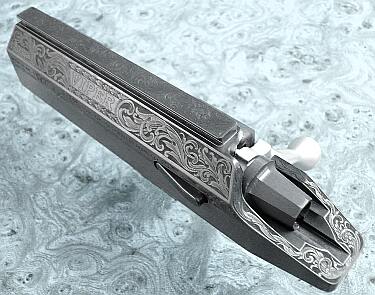

When Texas gunsmith Speedy Gonzalez set out to build the "ultimate PPC" for his own use, he wanted it to be as handsome as it was accurate. Here is his latest creation, a real stunner that combines some very trick components with old-world detailing. When was the last time you saw an engraved receiver on a "race gun"? This rig combines the best of both worlds--modern high-tech componentry with classic good looks.

Speedy's latest competition 6PPC features a one-of-a-kind engraved Stiller Viper action, with integral scope rail, SAKO Extractor and non-fluted bolt. The action sits in a new Millenium BR-X carbon-fiber stock built by Robertson Composites. The bold red-on-black marbled finish is how the gelcoat comes from Ian Robertson's factory--the stock has not been painted. The slick front rest is a titanium Ultra-Rest machined by John Loh with design input by Speedy. John built only two of these in titanium, one for himself and one for Speedy. The regular steel version runs about $725 including front pad. The Leupold Competition scope sits in quad-screw bedded rings from S.G.& Y. Precision Rifles. Speedy picked a very special barrel for this project--a 1:14 twist, 20.5", 6-groove barrel, the last original Pat McMillan-crafted barrel in Speedy's inventory. Speedy runs a .263" neck. Bushing size depends on the load and the condition of his brass. Speedy's match load is about 29.2 grains of the IMR 8208 "ThunderBird" powder (he stockpiled this great propellant years ago). Speedy feels that T-Bird may be the most user-friendly BR powder ever made: "Once you have a good load worked up with T-Bird, you can shoot it at most any location in the country, and in almost any conditions. It's not fussy about temperatures or humidity."

A Very Unique Viper Action, Two Years in the Making A Very Unique Viper Action, Two Years in the Making

This is no ordinary Viper action. The full engraving attracts your attention, but there are some slick "performance mods" Jerry Stiller added at Speedy's request. First, the action features a plain-Jane unfluted bolt, with a slight taper in the middle, a bit of a wasp-waist. Speedy prefers an unfluted design because it has superior wear characteristics. He's found, when working with an aluminum action such as the Viper, the sharp flutes on the bolt will wear the inside of the action faster. In the interest of reduced wear, he also requested a smaller-sized loading/ejection port. This provides for a larger front and rear receiver ring. With more receiver metal front and rear, the bolt bearing surface is enhanced. More bearing surface reduces point loading which, in turn, should result in less internal wear. We were surprised that Speedy did not order a drop port for his Viper. He explained: "I'm a bag squeezer, so I keep my forearm right where the cases would exit the drop port. I've used the drop ports, but given my shooting style, I prefer a conventional port." Speedy did decide to fit the bolt with a SAKO-style extractor. He believes this is easier to tune and can contribute to accuracy. Speedy told us: "With a conventional sliding plate extractor, like you find on the Stolle actions, there can be a bit of a side push as you chamber the round. I think this can affect the way the bullet enters the chamber. With the SAKO extractor there is no side-push so I can reduce the possibility of bullet misalignment. Yes you can tune a conventional extractor to lessen the side-push, but it takes a whole lot more work to get it right."

BR-X Stock--American Design, Canadian Craftsmanship

The BR-X carbon fiber stock represents a third-generation design. The original Millenium, built by Lee Six, was a hollow shell. The new BR-X is carbon fiber over a foam core. In Light Varmint trim, it weighs just 1.5 pounds. Speedy tells us: "the latest BR-X has a low center of gravity, slight pistol grip, and the angles are really straight and true. It tracks well in the bags, and won't lift out of the rear bag during recoil. That's one of the purposes of the wedge-shaped rear section."

Speedy looked at the various benchrest stocks, and, with input from Tony Boyer, he worked out a design that mirrored many of the better features of existing designs with some significant enhancements. The first thing you'll notice is that the geometry is very uniform. The flats on the side of the fore-arm are perfectly parallel. The underside of the fore-arm is seamless and completely flat. Speedy explained "one problem we've seen with stocks that have a mold seam in the middle is that sometimes the two halves of the mold don't mate perfectly. Sometimes the mold is mismatched so one side is on a different plane. That creates all kinds of handling issues. If the bottom of the stock is convex, even a little bit, you lose a lot of stability."

Much thought went into the rear section of the stock. Speedy and Tony found that many stocks would start off tracking well, but by the end of the string they were pulling themselves out of alignment. Speedy noted that with some more conventional designs, they tended to ride up out of the rear bag after two or three shots. The BR-X works differently. It uses a wedge design, rather than a radius, so it tends to drive itself down into the bag on recoil. The BR-X is not the only stock to use a wedge in the rear, but it is different than other wedge designs. According to Speedy: "On most other wedge stocks, the wedge tapers towards the pistol grip, making the 'V' wider towards the end of the buttstock. This will change point of aim as the stock moves. The BR-X has a wedge that is a constant 'V', with no taper from the end to the pistol grip. This does make the gun track better and stay on target better." Much thought went into the rear section of the stock. Speedy and Tony found that many stocks would start off tracking well, but by the end of the string they were pulling themselves out of alignment. Speedy noted that with some more conventional designs, they tended to ride up out of the rear bag after two or three shots. The BR-X works differently. It uses a wedge design, rather than a radius, so it tends to drive itself down into the bag on recoil. The BR-X is not the only stock to use a wedge in the rear, but it is different than other wedge designs. According to Speedy: "On most other wedge stocks, the wedge tapers towards the pistol grip, making the 'V' wider towards the end of the buttstock. This will change point of aim as the stock moves. The BR-X has a wedge that is a constant 'V', with no taper from the end to the pistol grip. This does make the gun track better and stay on target better."

Barrels--The Hunt for a 'Hummer'

Top 6PPC competitors often run through a number of barrels in the quest for a "hummer" that performs optimally. In addition to the Pat McMillen tube on this gun, Speedy uses barrels from Hart, Krieger, and Shilen. He's tried a few from some other boutique barrel makers and they shot well, but he wasn't satisfied with the barrel life. Some of them lost their competitive edge after just 500-600 rounds. He won't name names in print, but you can call and ask. When choosing a barrel, Speedy recommends that you invest the time and call a few well-known smiths who regularly compete in high-level BR matches. Find out what's working real well currently. Speedy says, "you can read the equipment lists from the big shoots, but the printed results can be deceiving. That winning barrel might have been produced a couple of years ago. Barrel-makers do have good runs and not-so-good runs. Do your homework and find out what's working best right now." Speedy prefers 6-groove barrels: "I've shot em all one time or another. It seems that the 6-groove barrels are easier to get to shoot. It seems at 200 yards bullets from a 4-groove barrel move more than from a 6-groove barrel. Both windage and elevation. I think Tony Boyer feels the same way." We asked about Speedy's signature "SpiderWeb finish". While the web design has esthetic appeal, there is a functional side as well: "Tests have shown that a bead-blasted barrel will shed heat faster than a highly polished barrel. With the SpiderWeb, we leave most of the bead-blast finish on the barrel, but the web effect gives the tube some visual appeal."

|  Speedy Speaks: Mastering the PPC Speedy Speaks: Mastering the PPC

Let me begin by saying that benchrest competition is the most difficult sport I've ever tried. For the newcomer, it can be daunting. From the very word "go" you are thrown to the wolves. Most new competitors have about a two and a half or three-year window. After that, if they are not meeting their expectations, they get fed up and leave the sport. Considering the time, effort, and money they may have expended in that time, that's an unfortunate outcome.

So, how does one improve as a shooter and get to the point where you are meeting your goals? First you need to break down the shooting process into its parts--gun handling, loading technique, wind awareness, time management, bag set-up, and what I call 'bench management'. Then you need a mentor. Benchrest is like golf--you can have the best equipment (best action, best stock, best rest) but you won't get far without a knowledgeable veteran to monitor your progress and observe your technique. Without a mentor, benchrest is a rough game to play and you can reach a frustration point after a couple of years.

If you don't have somebody who can sit and evaluate your loading style, bolt-working, follow-through, and wind-reading etc., you can develop bad habits that are hard to break. If there's no one to monitor your shooting and see what you're doing wrong, you'll keep making the same mistakes. So how does one find a mentor? Well it's not a bad idea to attend one of the shooting schools. But one-on-one training is best. Look for someone with a strong record in competition, but a person who is also patient. And when you find that person, show some loyalty. With most people who have been involved in the sport a while, if you show them allegiance, they will return that allegiance. |

6MM PPC Cartridge Guide  Developed by Louis Palmisano and Ferris Pindell (left and right in photo), the 6PPC is the "King of the Hill" in short-range benchrest competition, the most accurate cartridge ever invented. It completely dominates 100- and 200-yard Group BR Shooting. If you want to win in that game, you pretty much have to shoot a 6PPC, or some derivative of the 6PPC design. Easily made from Lapua 220 Russian brass, the 6mm PPC, like the 6mm BR Norma, has a small primer and small flash hole. The small flash hole/primer accounts for much of the 6PPC's superior accuracy, though nobody really knows precisely how or why. The "short, fat" shape and nearly straight body contribute to efficient, consistent combustion and good "chamber behavior". The 6PPC's case capacity, case size to bore ratio, and combustion properties seem to be just about ideal for the short 6mm match bullets. A 6BR can come close, but when the goal is shooting "zero" groups at 100 and 200 yards, the 6PPC is the clear winner. Currently most 6PPC shooters form their cases from Lapua 220 Russian brass. Both SAKO and Norma make factory-formed 6PPC cases, but these are not commonly used. The Sako 6PPC USA is slightly larger, and will not fit in most current match chambers. The Norma 6PPC brass is somewhat softer than Lapua brass. It works fine for varminting or fun shooting, but it will not hold up to the stout loads used in competition as well as brass formed from Lapua 220 Russian. Developed by Louis Palmisano and Ferris Pindell (left and right in photo), the 6PPC is the "King of the Hill" in short-range benchrest competition, the most accurate cartridge ever invented. It completely dominates 100- and 200-yard Group BR Shooting. If you want to win in that game, you pretty much have to shoot a 6PPC, or some derivative of the 6PPC design. Easily made from Lapua 220 Russian brass, the 6mm PPC, like the 6mm BR Norma, has a small primer and small flash hole. The small flash hole/primer accounts for much of the 6PPC's superior accuracy, though nobody really knows precisely how or why. The "short, fat" shape and nearly straight body contribute to efficient, consistent combustion and good "chamber behavior". The 6PPC's case capacity, case size to bore ratio, and combustion properties seem to be just about ideal for the short 6mm match bullets. A 6BR can come close, but when the goal is shooting "zero" groups at 100 and 200 yards, the 6PPC is the clear winner. Currently most 6PPC shooters form their cases from Lapua 220 Russian brass. Both SAKO and Norma make factory-formed 6PPC cases, but these are not commonly used. The Sako 6PPC USA is slightly larger, and will not fit in most current match chambers. The Norma 6PPC brass is somewhat softer than Lapua brass. It works fine for varminting or fun shooting, but it will not hold up to the stout loads used in competition as well as brass formed from Lapua 220 Russian.

Dimensions--Once a Wildcat, Always a Wildcat

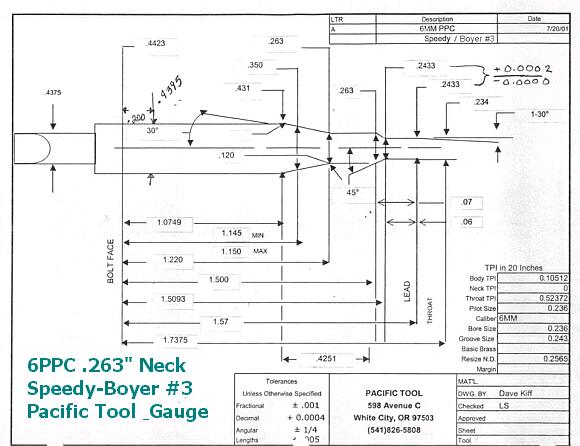

While SAKO has created an official SAAMI 6PPC round, called the 6PPC USA, most of the 6PPC shooters in North America are running tight match chambers cut with custom reamers. There will be variations from one reamer to another, enough so that custom dies are generally recommended for match guns. Here is a Dave Kiff reamer used by Speedy. He prefers a .263" neck because that works better than .262" when he needs to use his tightest bushings to get more neck tension.

Fire-Forming Cases Fire-Forming Cases

There are three basic methods to form 6PPC cases.

Method 1--Fire-Form with Pistol Powder, No Bullet: With this method, you load a case with pistol powder, seal the case mouth with wax or modeling clay, and then just shoot off the charge. There are many variations on the theme, using different loads of powder and various fillers, but we suggest just loading the case with Bullseye up to the neck, top with wax (NO BULLET of course!), and forget the fillers. This will produce very consistent cases, particularly if you use a dedicated fire-forming barrel with .002-.003" shortened headspace for a good crush fit. It's sensible to set up the fire-forming barrel with a no-turn neck, so you can neck-turn after fire-forming. If you are using a chamber with normal headspace (such as when fire-forming with your match barrel), we recommend you run an expander down the neck to get an outside diameter just equal to the chamber size. This helps with crush fit, and seals the chamber, reducing blow-by. For example, if you have .010" neck thickness, and a .262" neck, you want to expand the neck inside diameter to .242" (after springback). Since there is no bullet in place, the case-neck will go in the chamber even with this tight clearance. Note: you can buy expanders in various diameters, but you may have to turn down the diameter slightly to get just the right amount of expansion. WARNING: NEVER USE the FIRE-FORMING PISTOL POWDER in YOUR REGULAR LOAD WITH BULLETS--THIS CAN BE EXTREMELY DANGEROUS!!.

Method 2--Fire-Form with 6mm bullet and Full Load: The second method is to fire-form with a 6mm bullet in place using your regular rifle powder. To save wear on your precious match barrel, again, this can be done with a dedicated fire-forming barrel. It's fine to use a "throw-away" PPC barrel that has lost its accuracy, but you want to make sure the chamber is the same as your match gun, or your fire-formed rounds may not fit. You expand the brass with a 6mm expander, then turn the cases to fit your chamber. (You may wish to leave the very end of the neck a couple thousandths larger than the rest of the neck so you get a crush fit--you can then make a final neck-turning pass after fire-forming). Load a full charge, seat the bullets into the lands, and shoot. After initial fire-forming you'll want to shoot the cases one or two times in your match barrel to get a final perfect fit. Most shooters will then uniform the primer pockets, and some will ream the flash holes. Some shooters like to do a final neck-turning pass after fire-forming. Once you do the case prep you prefer, the cases are ready for competition.

Method 3--Load with .222 Bullet in 6PPC Chamber: The third method, loading a 220 Russian normally and shooting it in a 6PPC chamber, is less well-known but reportedly works well. Start with a 6mm fire-forming barrel chambered like your match barrels. You simply take the 220 Russian case, fill it with a normal charge of rifle powder (H322, Benchmarks, VV N133), and seat any inexpensive .222 bullet. Chamber the round and fire. This will blow the shoulder forward and expand the neck to your exact chamber dimension. The .22-caliber bullet just sails down the oversize bore (don't use your match barrel for this!). Reports are that this results in very uniform necks. After fire-forming, expand the neck and turn to your desired diameter. The only negative in this process is that you will be wasting bullets, so use cheap ones. Also, you'll need some kind of .22-caliber seating die. By contrast, with the no-bullet/wax-plug method you can basically fire-form at the bench with no tools other than a primer seater and a powder dipper. Thanks to K. Highfield of Sydney, Australia for this tip.

If you think this seems like a lot of work--you're not alone. If you're short on time or don't want to mess around with fire-forming, you can purchase processed 6PPC brass from a variety of sources including Bruno Shooters Supply, Hoehn Sales, and S.G.& Y. Precision Rifles. If you think this seems like a lot of work--you're not alone. If you're short on time or don't want to mess around with fire-forming, you can purchase processed 6PPC brass from a variety of sources including Bruno Shooters Supply, Hoehn Sales, and S.G.& Y. Precision Rifles.

S.G.& Y. has a dedicated lathe just for neck-turning PPC brass (photo at right). They can fire-form and neck-turn your cases to your exact specifications, using a set of pre-set Nielson "Pumpkin" tools. We've found the neck consistency of S.G.& Y's lathe-turned brass to be superior to what most shooters can produce with hand neck-turning tools--unless they have many seasons of practice. Brass and neck-turning images courtesy S.G.& Y. Precision Rifles.

Propellant Selections

The most popular 6PPC powders for Benchrest are: Vihtavuori N133, H322, and Benchmark. N133 is now used by most 6PPC competitors, with H322 second, and Benchmark a not so close third. Among the top fifty shooters at the 2004 Super Shoot, N133 and Federal primers were used by a large majority of the competitors. Historically, IMR 8208 (aka "Thunderbird") powder may be the best of all--many shooters feel it shoots well in nearly all conditions, so well that you can get by with the same load in most locations. Unfortunately, Thunderbird is no longer sold. Jackie Schmidt notes: "With the demise of the legendary 'unobtainables', ("T", Scottish 322, Thunderbird, old 2015), N133 has certainly become the powder of choice." While many feel Benchmark is a little too slow in burn rate, N133, H322, and Benchmark can all deliver outstanding accuracy. With all three powders, most first-rank shooters "load to the conditions" to eliminate temperature-induced variations. Benchrest competitors definitely "hot-rod" their cartridges, pushing them to the max given the conditions. Still, with the good Lapua Brass, 6PPC shooters can often make 100 pieces of brass last an entire shooting season. The elite shooters, however, usually prepare a new set of brass for major matches. Speedy tells us, "With the amount of time and money expended attending a major match, the cost of a new set of brass is insignificant. Before a big shoot, I'll fire-form 50-100 pieces in a separate barrel, then shoot each case once in my comp gun, and then they are ready for match use." The most popular 6PPC powders for Benchrest are: Vihtavuori N133, H322, and Benchmark. N133 is now used by most 6PPC competitors, with H322 second, and Benchmark a not so close third. Among the top fifty shooters at the 2004 Super Shoot, N133 and Federal primers were used by a large majority of the competitors. Historically, IMR 8208 (aka "Thunderbird") powder may be the best of all--many shooters feel it shoots well in nearly all conditions, so well that you can get by with the same load in most locations. Unfortunately, Thunderbird is no longer sold. Jackie Schmidt notes: "With the demise of the legendary 'unobtainables', ("T", Scottish 322, Thunderbird, old 2015), N133 has certainly become the powder of choice." While many feel Benchmark is a little too slow in burn rate, N133, H322, and Benchmark can all deliver outstanding accuracy. With all three powders, most first-rank shooters "load to the conditions" to eliminate temperature-induced variations. Benchrest competitors definitely "hot-rod" their cartridges, pushing them to the max given the conditions. Still, with the good Lapua Brass, 6PPC shooters can often make 100 pieces of brass last an entire shooting season. The elite shooters, however, usually prepare a new set of brass for major matches. Speedy tells us, "With the amount of time and money expended attending a major match, the cost of a new set of brass is insignificant. Before a big shoot, I'll fire-form 50-100 pieces in a separate barrel, then shoot each case once in my comp gun, and then they are ready for match use."

Loading Strategies--Should You Load on the Bench?

The majority of top 6PPC competitors still load their ammo on match day, playing with load weights in an effort to suit the charge to ambient temperature and humidity. While this allows you to get peak velocity on a cool day, and avoid over-charges in very hot conditions, loading at the bench is also a huge distraction, and you may find that on-site loading really isn't essential to success. Hall of Famer Jim Borden observes, "I have my ammunition already loaded for [major matches]. It seems to be working as both my rifles are consistently Agging in the low Ones. That's with a load of about 29.0gr N133, running about 3300 fps." Why does Jim pre-load when most competitors try to load to conditions? Jim answers: "Loading to conditions on match day can kill you. All you can do is go by memory and guess-timates. I've found if your rifle has good vibration control, you'll typically have an accuracy window of 100-125 fps. So I set my preloads for velocity in the middle of the accuracy window and that lets me shoot in any conditions. Studies by Jack Jackson convinced me we could let ammo sit for as long as a year and the accuracy will hold."

Projectiles -- Match Bullets Get the Nod

For competition, almost all 6PPC shooters are using 60-70gr match bullets from boutique bulletsmiths such as Ronnie Cheek, Allie Euber, Jef Fowler, Don Gentner, Brady Knight, Bart Sauter, and Zia Bullets. Bart Sauter's Ultra bullet has proven extremely successful, and Col. Billy Stevens used Ultras to win the 2005 Super Shoot. But there are many great bullets that can win. Lester Bruno was the 2004 Shooter of the Year, and he credits much of his success to his innovative boat-tail bullets: "I won the first match I shot with the new Bruno Boat-tails, and from then on I was consistently placing higher than ever before. I really believe that, more than anything else, switching to these bullets was the main reason I did so well in 2004". What's new on the bullet horizon? Well both Brady Knight and Zia Bullets have produced some 58gr bullets that are quite promising. The smaller bullet does offer both higher velocities and slightly less recoil. Zia recently released a 58gr 7.75 ogive match bullet. Zia claims "the slightly higher weight and better ballistic coefficient of this 'Zia Lite' bullet combined with 3550+ fps puts the 6PPC in a whole new ballgame." For competition, almost all 6PPC shooters are using 60-70gr match bullets from boutique bulletsmiths such as Ronnie Cheek, Allie Euber, Jef Fowler, Don Gentner, Brady Knight, Bart Sauter, and Zia Bullets. Bart Sauter's Ultra bullet has proven extremely successful, and Col. Billy Stevens used Ultras to win the 2005 Super Shoot. But there are many great bullets that can win. Lester Bruno was the 2004 Shooter of the Year, and he credits much of his success to his innovative boat-tail bullets: "I won the first match I shot with the new Bruno Boat-tails, and from then on I was consistently placing higher than ever before. I really believe that, more than anything else, switching to these bullets was the main reason I did so well in 2004". What's new on the bullet horizon? Well both Brady Knight and Zia Bullets have produced some 58gr bullets that are quite promising. The smaller bullet does offer both higher velocities and slightly less recoil. Zia recently released a 58gr 7.75 ogive match bullet. Zia claims "the slightly higher weight and better ballistic coefficient of this 'Zia Lite' bullet combined with 3550+ fps puts the 6PPC in a whole new ballgame."

Varmint shooters can utilize a wide range of 6mm bullets from 50 to 90 grains, but we think the 6PPC does best with bullets under 80 grains. The 58gr and 65gr V-Max shoot great from a 1:14" twist barrel, but Varminters may find a 1:12" barrel more versatile, as this can handle the heavier Varmint and hunting bullets, such as the 75gr V-Max.

Custom Dies Work Best Custom Dies Work Best

Most top 6PPC competitors run their ammo at pretty high pressures. Such pressures demand that cases be full-length sized each time they are loaded. But the trick is sizing the case just enough to allow proper feeding/extraction and no more. To achieve this perfect fit, nearly all the "top guns" use custom dies, precisely fitted to the dimensions of fired brass. Typically, a custom sizing die will reduce the case diameter at the shoulder .00075" to .001". The die will also allow for a little bit of shoulder bump. Nearly all the top shooters use bushings for neck-sizing. Having a variety of bushing allows you to compensate for brass that becomes work-hardened. You can also use bushings to tune loads for different bullets or conditions (tighter "grip" tends to increase pressure). For his .263"-necked brass, Speedy Gonzalez has a full set of carbide neck bushings, in .0005" increments from .256" to .261". He also has four different body-sizing dies, which allow him to choose the exact amount of sizing he wants, both at the shoulder and at the web. Most of us can't afford such a collection of dies, so you want to start with a good basic full-length die that brings in the shoulder a little less than one-thousandth. To check if your die is sizing properly, measure the diameter of a fired case right at the base of the shoulder and lock the calipers. Then run the case through the full-length sizing die. Put the calipers back on the sized case and then slide them down. The calipers should slide one-quarter to one-third of the way down the case. If the calipers can slide to the middle of the case, your die is sizing too much.

For bullet seating, hand dies used with an arbor press are favored by most 6PPC competitors. Wilson makes an excellent stainless micrometer-topped seating die that will produce excellent ammo with low run-out. For the ultimate in accuracy, you can have your gunsmith use the chamber reamer to create a true custom seater die. If you are going to the expense of a custom seater, it is worth fitting the die with a micrometer top. This makes it much easier to control seating depth.

Chambering and Barrel Twist

If there is a standard configuration among 6PPC rifles it is a 20-22" Heavy Varmint or Light Varmint taper barrel, 1:13-1:15" twist barrel, with a .262"-.263" Neck chamber. At the Super Shoot many of the best shooters favored a 13.5 to 13.7 twist. Most 6PPC shooters believe a .262" neck gives the best accuracy. However, Mike Bryant has built some very successful 6PPCs with .265" necks, and many notable shooters are experimenting now with .268" necks. That still requires neck-turning, but it can be done in one pass. Turning brass for a .262" chamber usually requires two or three passes for the best results. For varminters, we recommend a .271" or .272" no-turn neck. This lets you spend less time fussing with brass and more time shooting. Just fire-form the cases with a strong (but not max) load of powder and the bullets seated hard into the lands. Trim the cases to length after fire-forming and you're good to go.

6PPC--A Super Accurate Varmint Round 6PPC--A Super Accurate Varmint Round

The 6PPC cartridge is not just for hard-core benchrest competitors. When used in a no-turn chamber it is an extremely efficient, user-friendly yet deadly accurate varmint round. And you can buy a 6PPC varmint rifle from a number of respected firms such as Cooper Firearms, E. Arthur Brown, Kimber, and SAKO. Eben Brown, who runs E. Arthur Brown Company, explains that the 6PPC is a very user-friendly varmint cartridge: "Full-length size, prime, charge with powder, and seat a bullet... sounds like what you do with any other cartridge, doesn't it? In fact, the only difference with a 6PPC is that it has to be fired once (fire-formed) to expand to its final shape and size. But even fire-forming shots produce exceptional accuracy. With my lightweight falling-block gun, I shot several 3/4" groups while fire-forming at 100 yards, with my best group at nearly half-inch--so the time spent fire-forming was wonderful! In the photo, the parent 220 Russian case is on the left, while the fire-formed 6PPC case is on the right. We dimensioned our 6mm PPC chamber reamer to cut a chamber that fits Lapua 220 Russian brass closely without neck-turning. Naturally we recommend you use the Lapua brass for best results."

Editors' Note: We recognize that some aspects of 6PPC tuning and accurizing remain controversial. Poll ten Hall of Famers and you can get ten different opinions on topics such as neck tension, load tuning, primer/powder choice and bullet performance. This article is a work in progress. We invite comments about any of the topics discussed herein.

Acknowlegements: We would like to thank Boyd Allen, Jim Borden, Lester Bruno, Mickey Coleman, Allie Euber, Speedy Gonzalez, Brady Knight, Bart Sauter, and Zia Bullets, who all provided input on this article. However, if any errors appear, blame the editors, not them. We also thank Turk Takano for granting permission to use his image of Louis Palmisano and Ferris Pindell, fathers of the 22PPC and 6PPC cartridges.

| Bullet | Powder | Start

Load | Start

FPS | Max

Load | Max

FPS | Comments | | Zia 58gr FB | AA 2230C | 31.0gr | 3400 | 33.1gr | 3550 | 200 fps faster than 66gr | | Bart's 62gr FB | H322 | 28.0gr | 2800 | 30.1gr | 3300 | 100-yard load | | Gentner 65gr BT | H322 | 26gr | 3100 | 28gr | 3300 | 7.5 ogive for .050" freebore | | Knight 66gr FB | VV N133 | 26gr | 2820 | 28.3gr | 3150 | 7 & 9 ogive best | | Bart's 68gr Ultra FB | VV N133 | 28.2gr | 3150 | 29.6gr | 3300+ | Bart Sauter's Load | | Bruno 68gr '00' BT | 8208 'T' | 28gr | 3100 | 29.0gr | 3300+ | Lester Bruno's Load | | Euber 68gr FB | VV N133 | 25gr | 2752 | 29.2gr | 3200+ | Allie Euber Load | | SG&Y 68gr FB | IMR 8208 (Thunderbird) | 28.8gr | na | 29.2gr | 3200+ | Speedy's Load | | Nosler 70gr BT | Benchmark | 28gr | 2800 | 29gr | 3149 | Hodgdon Data | | 6PPC Loads -- Always start 10% low and work up -- Lapua Brass Only |

|---|

|

Did You Enjoy Reading this Article? If So, You Can Help Support

6mmBR.com by Making a Small, Secure Contribution.

Copyright © 2005, 6mmBR.com, All Rights Reserved. No reproduction of any content without advanced permission in writing.

Topics: 6mm, 6mm BR Norma, 6BR, 6BR Long, 6PPC, 6 PPC, .308, IBS, NBRSA, Stiller, Viper, Python, Robertson Composites, BR-X, Carbon Fiber, Score, Group, Agg, Aggregate, Benchrest, 6mm Improved, Light Gun, LV, HV, 6PPC, Hart, Krieger, 300m, 600m, 1000 yards, Jewell, Benchrest, BR, Bench Rest, rifle accuracy, Recoil, Bipod, Thunderbird, IMR 8208, Hodgdon Powder, Varget, H4350, Reloader, Vihtavuori, Lapua, Scenar, Competition Shooting, Stocks, Leupold, Krieger, Kelbly Klub, Adamowicz, Lee Six, Borden, barrel, reloading, powder, case forming, neck-turning, Lapua Brass, bullets, precision, SG&Y, S.G. & Y., Stiller, Speedy, Speedy Gonzalez, Tony Boyer.

|