Profile:

Profile: Jim Carstensen is the owner and lead engineer for JLC Precision, in Bellevue, Iowa. With over a decade of precision machining experience, he specializes in crafting custom dies and die conversions. JLC Precision also performs corrective work on Leupold benchrest scopes, and Jim does expert gunsmithing on both benchrest and varmint rifles.

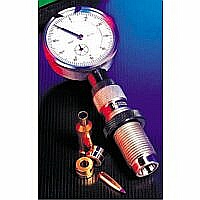

6mmBR.com asked Jim about the custom full-length bushing dies he produces. Here is his analysis.

The JLC Bushing Die ConversionI've converted dies to accept sizing bushings for 10 years. I can take any die, either a neck or full length die, (with the exception of a carbide die) and convert it to resize the neck with a bushing. This allows you precise control over neck tension without the disadvantages of an expander ball. They work best with necks that have been outside neck-turned, so as to remove the inconsistencies that you have with virgin brass. Turned necks will also result in the bullet being centered better in the chamber. I think a majority of the growth that reloaders get in their brass is due to pulling the expander ball back out of a resized neck.

Dies That Work Best for the 6mm BRNow as to the 6mm BR, I don't think there is a good standard die available for it. Most over-resize the front portion of the case near the shoulder, and don't resize the base of the case enough, if at all. The Redding body die (photo top left) is an exception to this. I use these and am able to open them up for bushings and install a decapping system. If you want a Bushing Die conversion done, I suggest you get a Redding 6BR body die and we will use this as the "donor" die core, which will then be honed and converted to bushings. Another option, if you need a die that is tighter on the base, is to use a small base body die. The procedure is the same, up to a point. This die will oversize the brass coming out of a chamber designed for Lapua brass.

Custom Honing the Conversion DieWhen making a JLC conversion Die, I don't just fit them for bushings. I measure your fired cases, and then start honing and polishing the die core to match. I will periodically stop to resize a piece of brass and check it against a fired case. This can take a long time, depending on the size of the chamber. I feel that the front of the case just below the shoulder should be resized about .0005", and the base resized .001". I also think the shoulder, or datum line needs to be pushed back no more than .001". This is what I strive for compared to brass that has been fired several times. It is the honing process that I do that makes the JLC conversion different and (I believe) better, than a standard Redding Type S full-length bushing die. The Type S full-length bushing die works the same way as my conversion does, in the sense that it sizes both the case body and the neck (by way of bushings). However, the Type S die, out of the box, will not be honed to fit your fired brass. Mine will.

These resize dimensions stated above (.0005" shoulder reduction, .001" base reduction), will work well with all chamberings I have encountered. When working with a larger capacity case (the 338 Lapua Magnum for example), I will increase the amount of resize slightly. I feel the resize on the base of the case is the most important component in achieving satisfactory brass life. Resizing with a die with the correct shoulder/base dimensions, and using it every time you reload, will result in the longest case life and easiest bolt operation. If you wait until the brass is getting hard to chamber and extract before resizing, most likely it will never work well again. This is because of the memory effect of the brass case. Once it gets to an oversized state, after resizing, upon firing it will simply stretch back to the same condition, and extract hard again.

Dies Made from Chambering Reamers--Why They're Not a Good ConceptYou may have heard of "bump" dies. These are made with the same reamer used to cut the chamber. They won't resize the sides and base of the brass, but they will bump the shoulder back, decap, and resize the neck with a bushing. In my opinion, they are a waste of money. After very few firings, the brass will start getting tight, and there's nothing to be done about it. You could bump the shoulder back an excessive and dangerous amount to ease chambering, but then a case separation is imminent.

If the action bolt is clicking or popping at the top of the bolt lift, it indicates that the brass is too big near the base. Once you start getting this, you might as well throw the brass in the garbage, as it will be impossible to stop when using full power loads. I think this is the most common complaint with 6mm BR or 6 PPC chamberings. If the bolt closes and opens hard throughout the whole stroke without the pop at the top, this indicates the shoulder needs to be pushed back.

A "Full Custom" Die -- The Total SolutionI can't run any reamer into the body of a factory die to change the dimensions. Dies are too hard to modify this way. If a die that is small enough to begin with can't be found, I can make a full custom die. I have total control over the amount of resize and where the resize is done at. I make a hardened bushing die with a decapping system. I work off fired cases for that chamber. This will cost around $200.00, but it will be a perfect die for the chamber for which it was made. Designed to be used after every firing, the dimensions will give the ideal amount of shoulder bump and body-sizing, no more, no less.

JLC Precision (Jim Carstensen)

jlcprec@netins.net13095 450th Ave

Bellevue, IA 52031

Shop phone: (563) 689-6258, cell: (563) 212-2984

Other JLC Precision Products

Other JLC Precision ProductsIn addition to our die conversions and custom full-length bushing sizing dies we make a benchrest seating die for use with arbor presses. This is similar to a Wilson hand die with micrometer top. But it is much more precise. Frankly, we think it is the best seating die you can buy for the 6BR, bar none. The adjusting top is equipped with a click indexer. Unlike other seating dies, one click provides exactly .001" in seating depth change. With this die bullet-seating is no longer a guessing game. Let's say you want to bring the bullet .005" closer to the lands. Just dial in five audible clicks and you are there, and you can have confidence in the setting. Price is about $150.

Leupold fixed-power competition scopes are known to have issues with tracking and repeatability. This is caused by shortcomings in the mechanism that moves the reticle up and down and left to right. The parallax adjustment also has a lash problem. I do an inexpensive conversion to the Leupold BR scopes that makes your scope track properly, with precise, repeatable windage and elevation adjustments. You may be surprised at the immediate improvement in your groups.

Copyright © 2004, 6mmBR.com, All Rights Reserved. No reproduction without advanced permission in writing.